What are the key production process steps for PET thermal matte silver paper?

The key production process steps of PET thermal matte silver paper mainly include the following stages:

- Pretreatment stage

Substrate preparation: Select high-quality PET film as the substrate to ensure the flatness, smoothness and dimensional stability of the substrate. - Coating stage

Primer treatment: Primer treatment is performed on the PET substrate. This layer is mainly used to improve the surface properties of the substrate, such as increasing adhesion and improving wettability, etc., to provide a good foundation for subsequent coating.

Matt silver coating coating: After the primer is dried, the matte silver coating is applied. Matt silver coating usually contains specific silver pigments, adhesives and other additives, and the thickness and uniformity of the coating are precisely controlled to achieve the desired matte silver effect.

Pigment selection: Use specific silver pigments that can present a matte silver effect.

Adhesives and additives: The adhesive is responsible for fixing the pigment on the substrate, and the additives are used to improve the processing performance and stability of the coating.

- Drying and curing stage

Drying treatment: After the matte silver coating is applied, drying treatment is performed to remove the solvent in the coating and initially cure the coating.

Curing treatment: Curing treatment is carried out by heating or UV irradiation to completely cure the adhesive in the coating and form a stable matte silver surface.

- Post-processing stage

Surface finishing: Further finishing treatment is carried out on the matte silver surface as needed, such as calendering, polishing, etc., to improve the surface finish and flatness.

Quality inspection: Quality inspection of the finished product, including tests on the uniformity of the matte silver effect, color saturation, adhesion, weather resistance, etc., to ensure that the product quality meets the standards.

- Winding and packaging

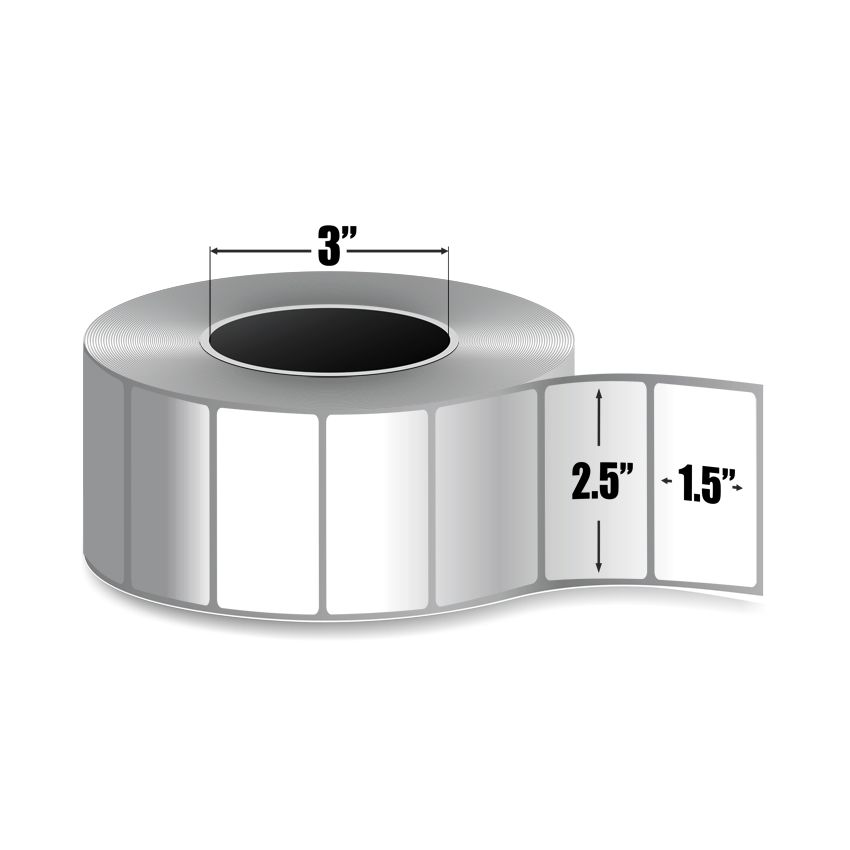

Rolling: The qualified PET thermal matte silver paper is rolled into a roll for subsequent processing and use.

Packaging: The rolled PET thermal matte silver paper is packaged to protect the product from the external environment.

In summary, the key production process steps of PET thermal matte silver paper include pretreatment, coating, drying and curing, post-processing, winding and packaging. Each stage requires strict control of process parameters and operating procedures to ensure that the quality of the final product meets the requirements.

Related recommendations

-

How does thermal paper printing work? Why does the writing disappear? Can the disappeared writing be restored?

349Thermal paper, a special paper that occupies most of the fields of receipts, faxes, and labels, has text that can easily disappear over time. Why is this?If you need to restore the information on it, is there a way to do it? The secret of thermal...

View details -

A Go-To Guide for Barcode and Shipping Labels

301In the early morning of June 26th, 1974, a man named Clyde Dawson stopped into a Marsh’s supermarket in Troy, Ohio to pick up a 10-pack of Wrigley’s Juicy Fruit gum. Rather than record the transaction by hand, the cashier simply scanned the barco...

View details -

How To Fix Printer Alignment Issues

342When it comes to printing sheet labels, the last thing you want is for the design to be off. This not only wastes time but also supplies you’ve spent money buying. Sometimes labels look good on your computer screen but the design prints...

View details -

What are the main production costs of PET thermosensitive matte silver paper?

316The production cost of PET thermosensitive matte silver paper mainly includes the following aspects: First, raw material costs 1.PET substrate: PET (polyethylene terephthalate) as the main substrate of thermal matte silver paper, its price fl...

View details

Lable,Blank Labels|

Lable,Blank Labels|

HelloPlease log in